Crucial Considerations for Ensuring High Quality and Durability in Utilized Engines

When considering the purchase of a used engine, guaranteeing its quality and long life calls for a complex method. Maintenance background is a pivotal variable, as it gives insight right into the engine's past treatment and possible future dependability. Performance screening is also crucial, using a picture of the engine's functional effectiveness.

Engine Background Evaluation

In the world of utilized engines, a thorough engine history examination is paramount to ensuring high quality and dependability. Recognizing an engine's past can provide critical understandings into its performance abilities and potential future longevity.

In addition, examining any kind of background of repair work or replacements is essential. Engines that have actually gone through significant repair work might have underlying problems that might resurface. Recognizing the context of such fixings, whether as a result of making defects or proprietor carelessness, is essential in developing a detailed assessment. Analyzing the engine's gas mileage can serve as an indicator of wear and tear. Reduced gas mileage engines are typically better, however it is additionally vital to consider just how those miles were collected. An engine used primarily for long-distance freeway driving might be in much better problem than one subjected to regular stop-and-go city website traffic.

Basically, an exhaustive investigation into an engine's history is important for making informed investing in decisions. used engines for sale.

Comprehensive Examination Overview

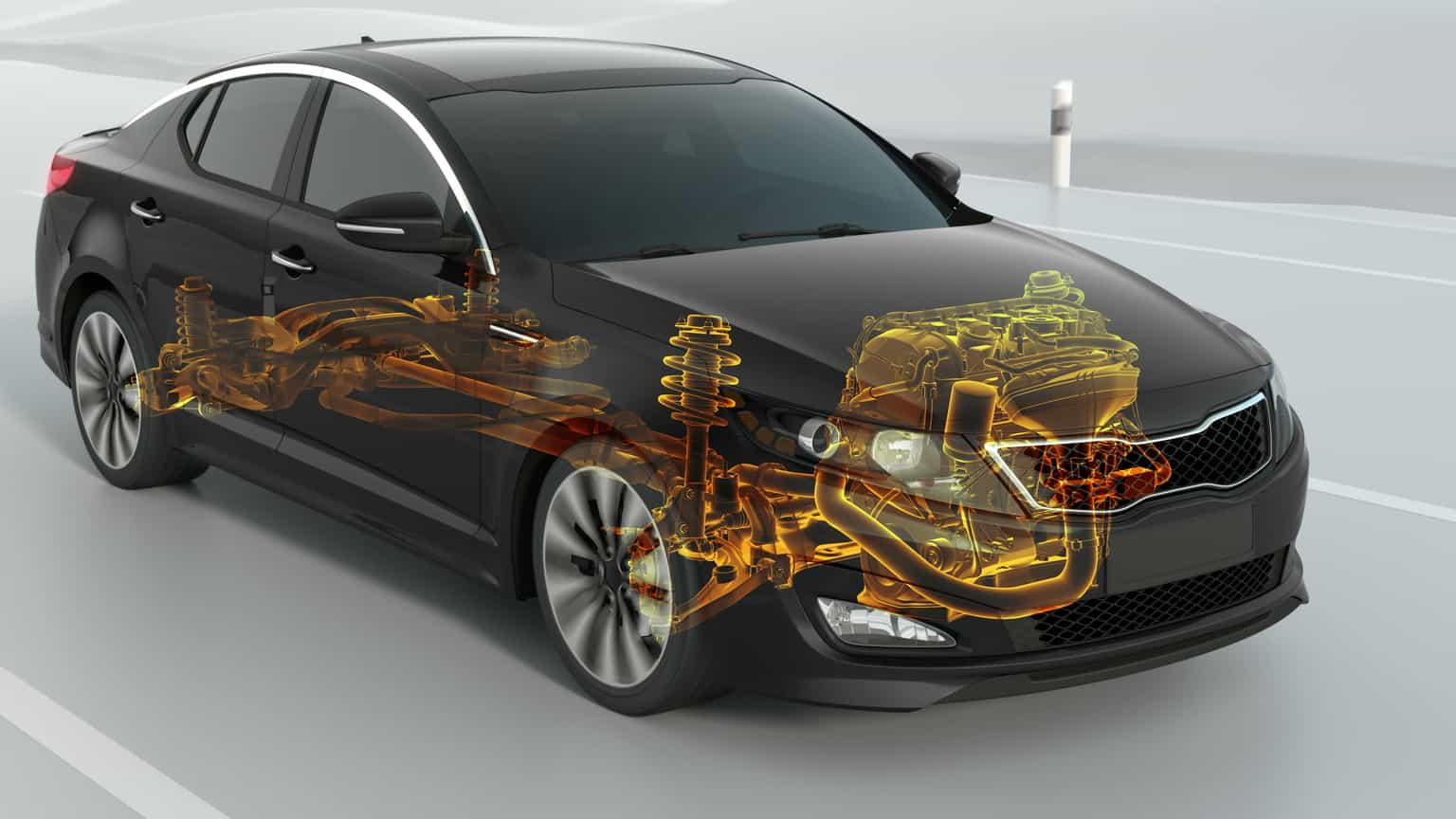

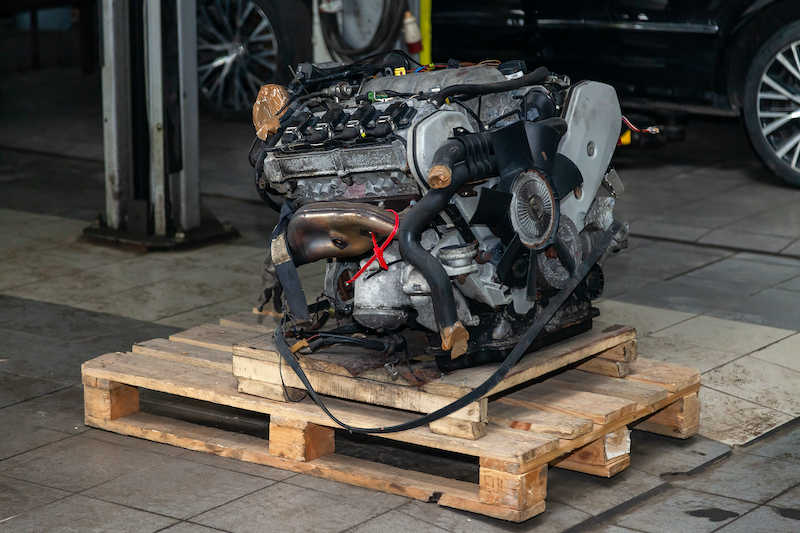

While comprehending an engine's background supplies important context, a detailed assessment is the next action to guarantee its present condition straightens with historical information. The inspection needs to start with a visual assessment, looking for signs of leaks, deterioration, and unusual wear. Check the exterior for oil stains or coolant marks, which may indicate underlying issues.

Next, review the engine's placing system for any loosened bolts or problems that could influence efficiency. Pay very close attention to the problem of belts and hose pipes, as these parts are important for optimum engine functionality. Analyze for splits, fraying, or any indicators of degeneration.

Identifying Damage

Recognizing indications of deterioration is vital for evaluating a used engine's long life and dependability. It involves a careful assessment of various engine components to establish their present state and prospective future performance. Common signs include visible deterioration, which can affect metal parts and compromise structural honesty. Corrosion on or around the engine block, cyndrical tube heads, and exhaust manifolds is particularly concerning.

An additional important aspect is evaluating the engine's seals and gaskets. In addition, irregular noises during engine operation, such as knocking or ticking audios, might indicate inner damages or too much wear on relocating components like pistons or bearings.

The problem of belts and tubes is similarly vital, as they play a crucial function in the engine's general feature. Broken or torn belts and brittle tubes are indicators old that can cause engine failure if disregarded. Checking out the oil problem and filter can give insights into previous maintenance methods, as dirty oil or stopped up filters suggest forget and look these up increased wear.

Efficiency Screening Essentials

Evaluating the deterioration of engine components establishes the phase for a detailed assessment with performance testing. Performance testing functions as a vital action in determining the functional stability of an utilized engine. By replicating real-world problems, it examines the engine's capability to provide power effectively and dependably. Key metrics consist of horsepower, torque, fuel performance, and discharges degrees. This information supplies valuable insights right into the engine's current performance and helps determine prospective concerns that may not be promptly visible.

Using dynamometers is a common technique in efficiency screening. These tools measure the engine's outcome across various conditions, offering a thorough profile of its functionality. In addition, on-road screening matches dynamometer assessments by observing engine actions under common driving circumstances, ensuring it satisfies the required criteria for both safety and security and performance.

These tools examine engine management systems, recognizing faults in digital elements that could influence performance. Comprehensive screening not just validates the engine's functional condition yet additionally aids in forecasting future maintenance requirements.

Maintenance and Treatment Tips

Appropriate upkeep and care are vital to lengthening the lifespan of a used engine and ensuring its constant efficiency. Normal oil modifications are extremely important; utilizing the maker's suggested oil kind and grade can prevent extreme damage. Additionally, oil filters must be replaced concurrently to preserve optimum lubrication and tidiness within the engine.

Checking liquid levels, consisting of coolant, transmission fluid, and brake fluid, is important. Ensuring these liquids go to proper degrees assists stop getting too hot and other mechanical issues. Examining belts and tubes for signs of wear, such as cracks or fraying, can avert prospective failures that may lead to costly repair services.

Regular assessment of the go to this site air filter is also necessary, as a tidy filter makes certain effective air movement and combustion, thus enhancing engine efficiency. Trigger plugs need to be checked and changed when needed to maintain effective fuel combustion and stop engine misfires.

Last but not least, routine analysis checks utilizing expert devices can recognize possible problems prior to they become substantial troubles. By adhering to these upkeep and care suggestions, utilized engine proprietors can ensure their engines remain trusted, effective, and efficient in performing well over an extended duration.

Conclusion